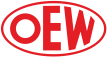

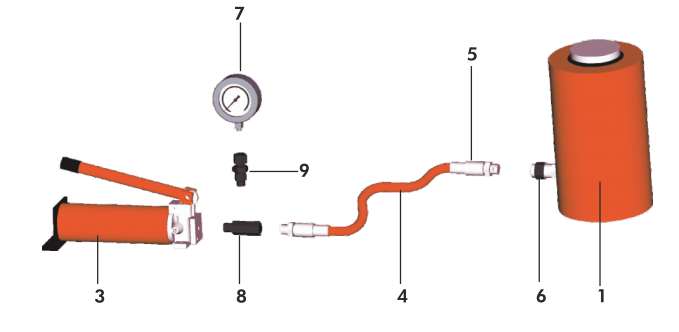

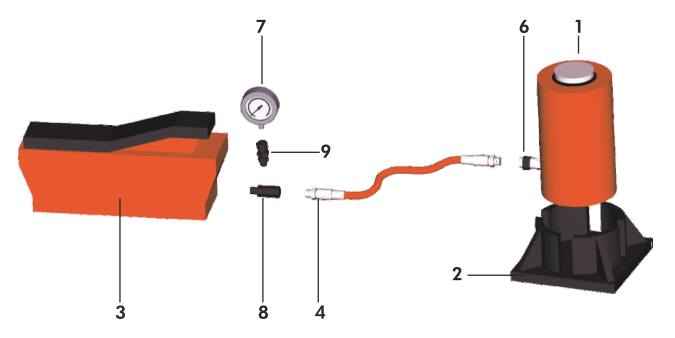

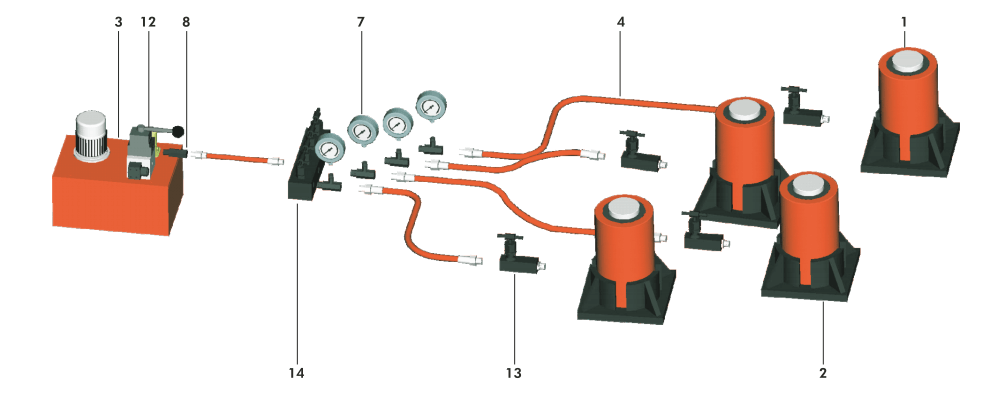

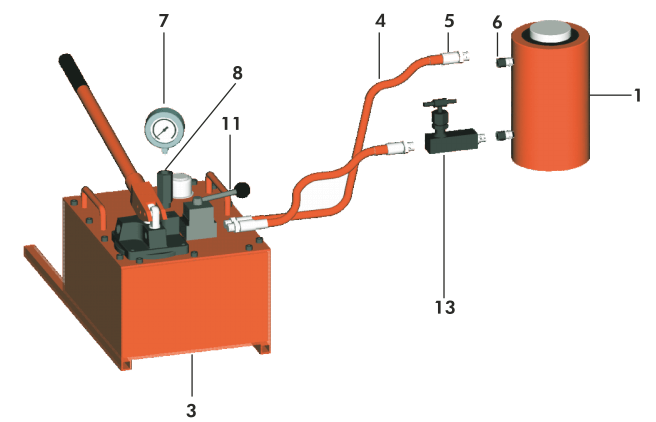

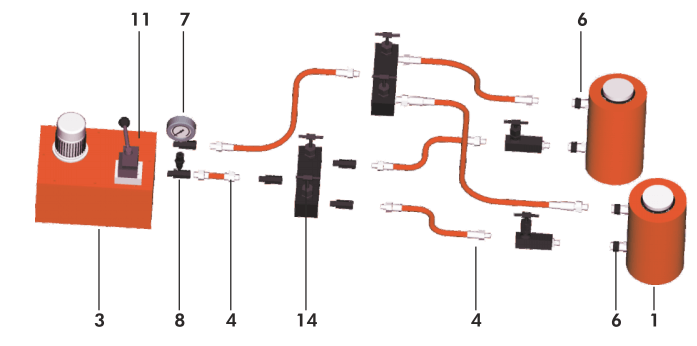

System Set-ups

- CYLINDER – Generates hydraulic force.

- CYLINDER BASE PLATE – Used for application where additional cylinder stability is required.

- PUMP – Provides hydraulic flow end pressure.

- HOSE – Transfers oil.

- MALE COUPLER – For quick connection of the system components to the hose end.

- FEMALE COUPLER – For quick connection of the Hose end to system components.

- PRESSURE GAUGE – Indicates system pressure.

- GAUGE ADAPTOR – For easy installation of pressure gauge.

- SWIVEL CONNECTOR – Allows proper alignment of valves and/or gauges. Used when units being connected cannot be rotated.

- AUTO-DAMPER VALVE – For gauge protection against fluid turbulence.

- 4-WAY DIRECTIONAL – Control Valve controls the direction of hydraulic fluid in a double acting system.

- 3-WAY DIRECTIONAL – Control valve controls the direction of hydraulic fluid in a single acting system.

- SAFETY HOLDING VALVE – Controls load descent in lifting application.

- MANIFOLD WITH NEEDLE VALVE – Allows distribution of hydraulic fluid from one power source to several cylinders and regulates the flow of hyd. fluid to or from the cylinder.