Impulse

IP 175 and IP 160 are available in Yamuna, Oriental, Hamburg, Mumbai, and Abu Dhabi casings and IP 130 is available in Brussels, Mini Mumbai, and Hamburg Canopy

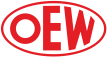

Reciprocating Pumps (available in 3 sizes)

• IP 130• IP 160

• IP 175

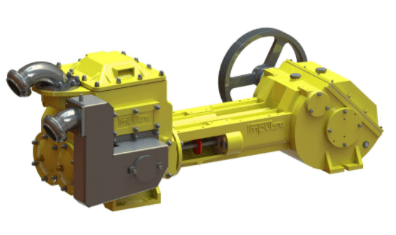

Screw Impeller Pumps (available in 5 sizes)

• SIP 100• SIP 150

• SIP 200

• SIP 250

• SIP 250 (High Flow)

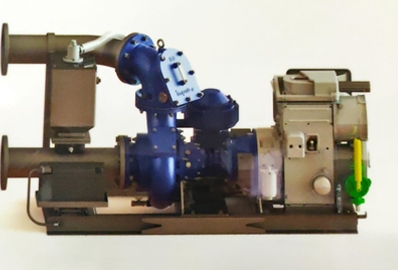

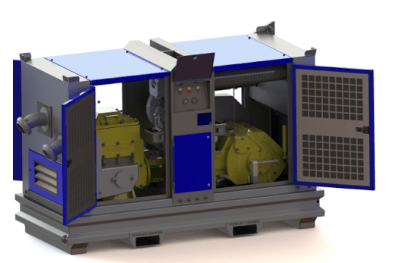

Soundproof Canopies

Yamuna (Diesel) • Oriental (Diesel and Electric)• Hamburg (Electric)

• Brussels (Diesel)

Open Structures

• Mumbai (Electric)• Abu Dhabi (Diesel)